CD (Critical Design) Cross Bearing

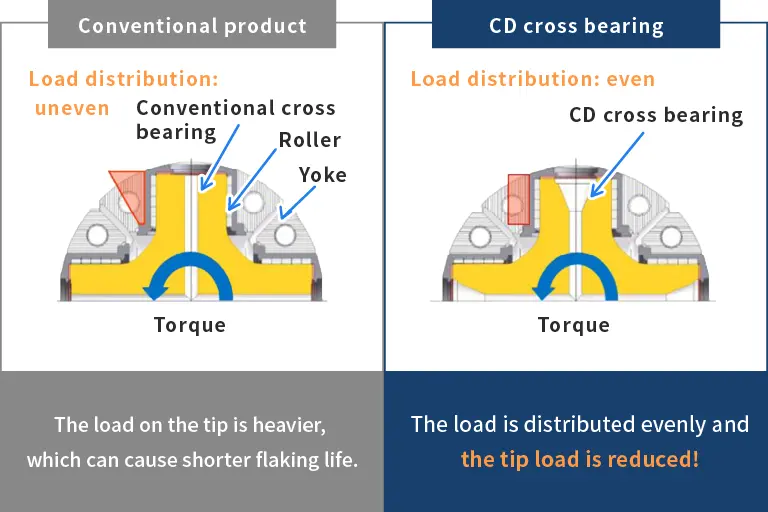

The load on cross bearings generally tends to be concentrated on the tip.

When flaking of the tip area is significant, early flaking of the tip can be reduced by forming a countersink on the cross inner surface to even the load.

* Evaluation results based on our experiments and FEM analysis

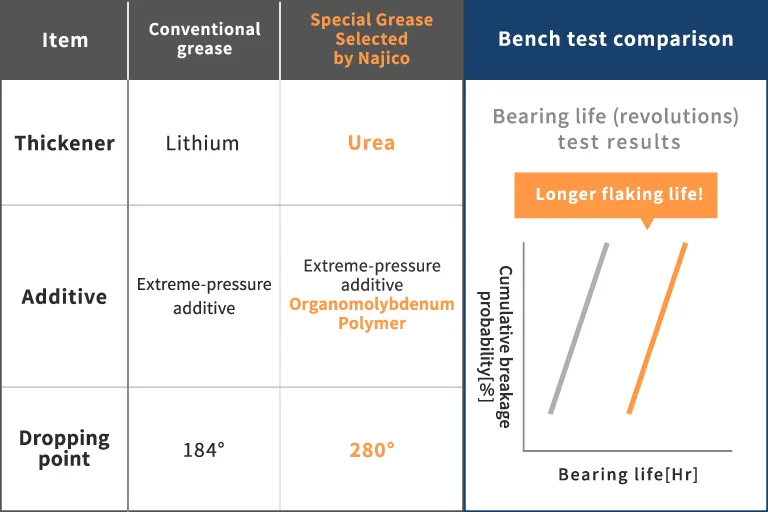

Special Grease Selected by Najico

The special grease which we strictly selected can be expected to improves oil film retention on bearingrolling surfaces compare to our standard grease.

* Evaluation results based on our bench tests

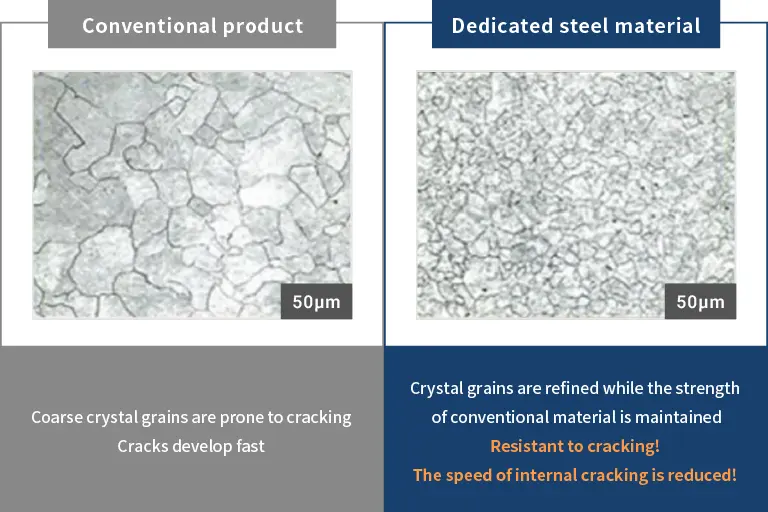

Dedicated Steel Material for Cross Bearings

For the material for cross pins for universal joints, we have developed a dedicated steel material with a significantly increased rolling fatigue life and the strength of conventional Ni-Cr-Mo steel. With refined crystal grains, the flaking life can be extended.

* Evaluation results based on our bench tests

TSUA-0286-4B_Life Extension Series_Dedicated Material for Cross

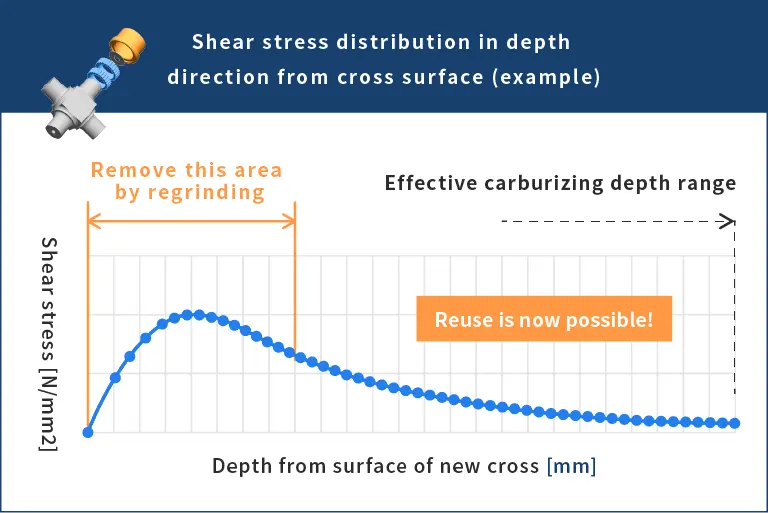

Cross Recovery

Before the rolling surfaces of bearings reach the end of their flaking lives, we regrind the surfaces of the outer race and cross pins to remove areas worn by rolling and restore their surfaces. This extends the cross bearing’s service life, helping reduce running costs.

Hirth Serration

When installing a universal joint, the flange surface of the mounting part generally design with flat key in Japan, but in other countries, a tooth shape called a hearth serration is commonly used. We can also desing the flange surface with hearth-serration type upon your request, so please feel free to contact us.

These are just a few examples. We also make many other efforts and proposals to suit our customers’ needs.